- Home

- Our Products

- Factory Products

- Diamond Tools

- Diamond Tools for CNC Machines

Diamond Tools for CNC Machines

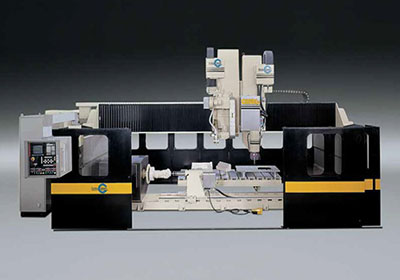

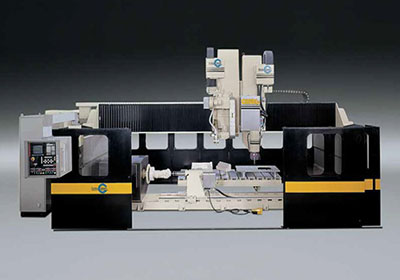

MILL4X

In one single cnc 3/4 axes machines all the shaping and lathing functions are gathered.

MILL4X is a numerically controlled machining centre from 3 to 4 axes, which groups in a single unit all the functions of a former and a lathe.

MILL4X results from 25 years manufacturing experience, which combines the best technologies with a simplicity in setting up work for forming, routing, engraving, milling, sculpting, sawing, polishing and lathe work on marble, granite, all types of stone and glass. MILL4X is a high output machine both for on-line production and for single, one-off pieces.

The axes are driven at high speed by brushless motors combined with ball bearing screws, while lasting quality and precision are assured by linear guides with ball runners, moving parts protected by PVC bellows and a centralised oil lubricating system.

The mobile bridge technology makes MILL4X a modular machine since the supplementary application of the lathe system or the extending of the work area can be done in any moment, depending on the customer requirements.

MILL4X

Omag is a machine using an innovative engraving device based on laser technology in order to get high resolution engravings.

LasiMark is an innovative tool based on laser technology.

An infrared laser beam is focused onto the surface to be engraved, locally the optical power density is sufficient to break the stone structure. The head is mounted into the numerically controlled machine tool like a normal mechanical tool.

LasiMark electronics combined with the software driver synchronises the laser pulses and the power controller to the movement of the machine tool axes plotting the desired images.

Lathe94TE

Columns, balusters, vases, balls, ovaloid, helical columns, Doric columns in marble, natural stone coverings, granite, onyx, crystal, are some of the types of articles and materials, which can be obtained through our Lathe94te.

Blade5

Efficient and highly reliable CNC milling machine; it is projected for operations with marble, stone and granite sawblades.

The technology, precision and the reliability of a numerical control working centre make this type of machine, which has been built to work with a blade on marble, stone or granite, uniquely efficient and highly reliable.

The high speed of the movement of the axis is guaranteed by a brushless motorization combined with ball bearing screws. The sliding movement on linear guides rails and ball bearing blocks the protection of the moving parts with PVC bellows and a centralised oil lubricating system guarantee quality and durability.

Tower7

The available size range makes it possible for customers to make the best possible choice for their specific machining needs, thus ensuring a perfectly targeted purchase Nonetheless, the precision engineering also allows threedimensional machining, low reliefs, inlays, kitchen tops,arches, capitals, sculptural columns.

For any potential need TOWER,thanks to a 54 HP electrospindle,also designed by OMAG, is able to use remarkable diameter ( 1.450) disks, highly suitable for any milling, roughing and shaping need.

Area5

Milling and shaping 5-axes machine, both manual and authomatic.

DISEGNI PROFILE

PROFILES DRAWINGS

Crea segmento - Segment creation

Cerchi archi spline curve - Circle, arc, spline, curve

Rettangoli - Rectangles

Poligoni - Polygons

Lavorazioni su profili - Machining on profile

Sgrossatura - Roughing

Sagomatura - Shaping

Finitura - Finishing

Spatolatura - Side milling